Main goals

- Having fun while working on the project

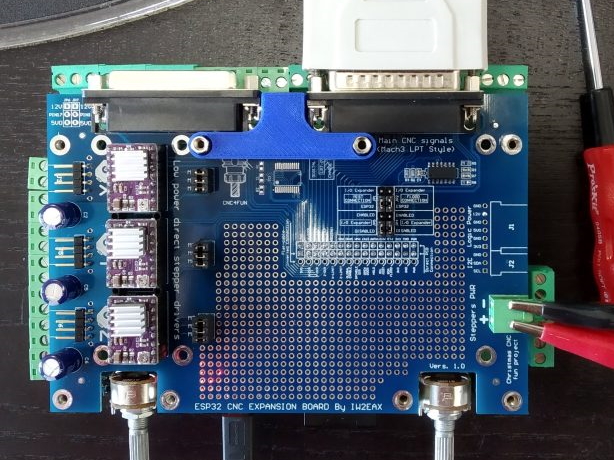

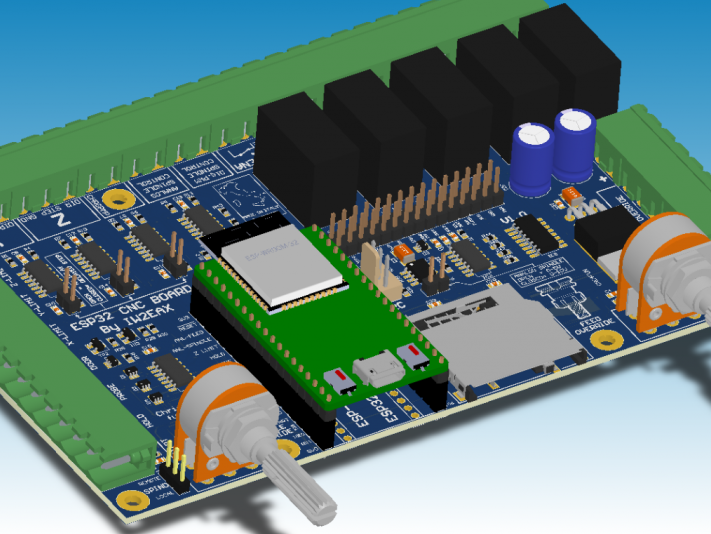

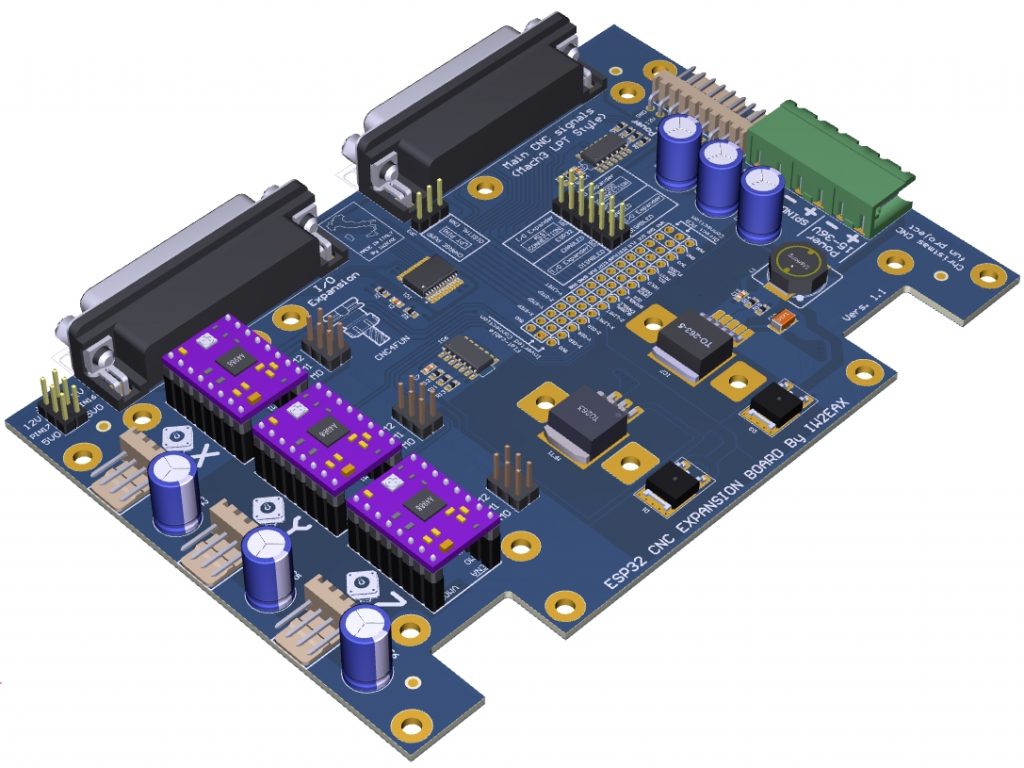

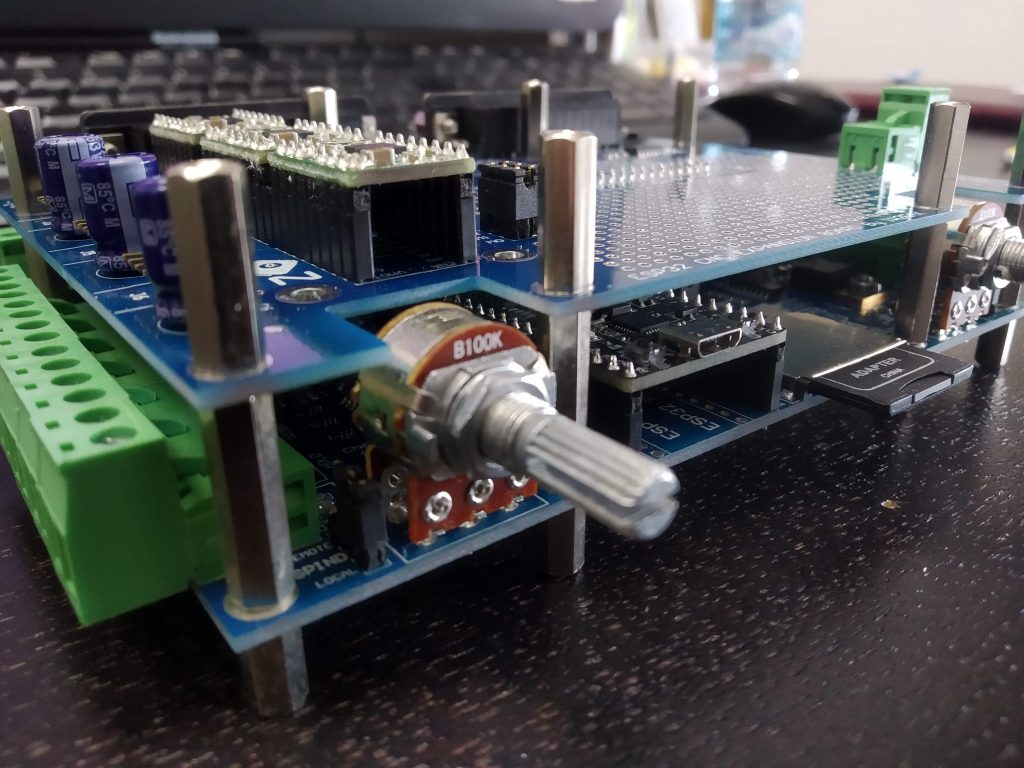

- Using low-cost hardware resources

- Having a versatile board that can easily be adapted to the various types of self-built CNCs

- Implementing basic adaptations to the logical levels and filtering the I/O signals

- Providing direct connection to high-power servo controllers through various connectors

- Providing good compatibility with the various already-existing servo controller boards of amateur CNCs that are still using MACH3 LPT-like ports

- Embedding direct small stepper drivers like those normally used in 3D printers

- Generating a square wave signal for the “charge-pump ENABLE” signal used by those driver boards (typically MACH3) that need it

- Supporting dual-mode spindle speed control, both via PWM and via an analog signal for those spindles whose speed regulation is done by reference voltage (0-5V or 0-10V)

- Providing wiring diagrams and documentation that can be accessible to other people who want to make new software/hardware variations on the board.