Main Features

In addition to the basic features of Bart Dring’s project, I added two functions that I personally find very important for a safer use of CNCs:

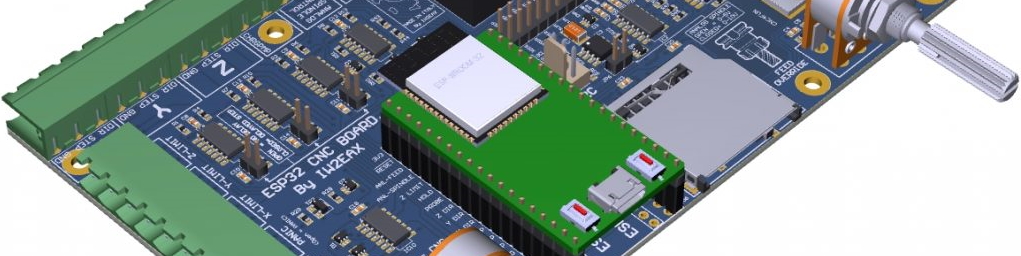

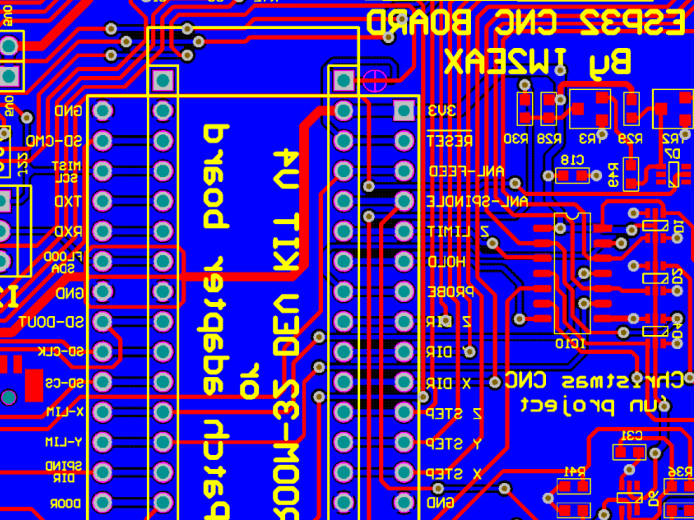

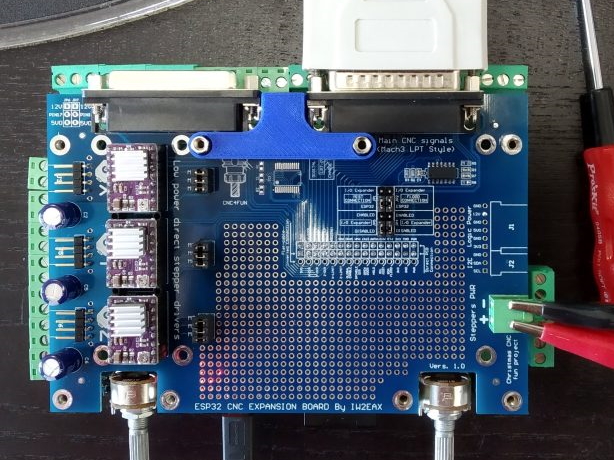

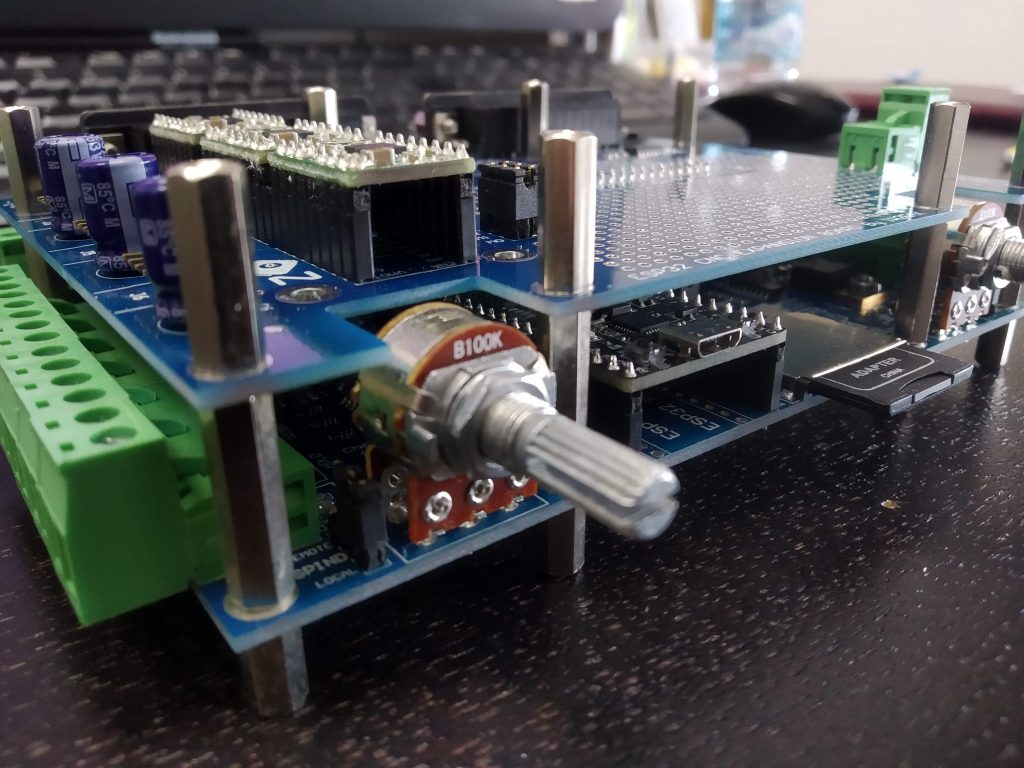

- A potentiometer for real-time MASTER override of the cutting feed speed (basic, but essential)

- A potentiometer for real-time MASTER override of the spindle feed speed (very useful, but not essential)

The first one in particular is essential to safely verify that, when starting a new work, there are no catastrophic errors, which can range from simple damage and tool crashes to serious injuries to the user caused by stray parts that can hit like bullets. CNCs are dangerous machines, and errors ALWAYS have consequences; in the most unfortunate cases, the consequence may be the price of one’s LIFE!

Having a controller with hardware overrides was essential to me. Given the availability of analog inputs on the ESP32 chipset, I therefore set up the hardware and modified the source code to implement this function.

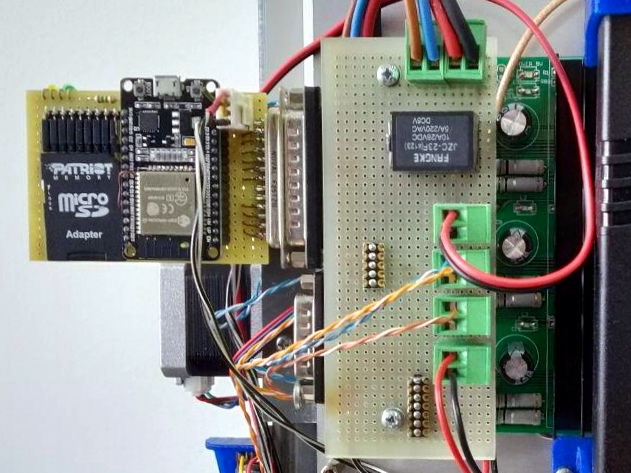

The latest change I made to the original project, in anticipation of future developments, was adding an expansion with 14 I/O digital lines and providing access to the I2C bus, in order to implement other future features such as adding MPGs, adding the vacuum pumps on/off function, etc.